Roberto Grassi –

The suction cup is a gripping technology commonly used in the modern industrial technology. Nowadays volume manufacturing machines adopt this system to handle objects with the most different shapes and the use of the vacuum technology is diffused and appreciated. There is however a real world, still scarcely known, where suction cups have been applied to robots according to the opposite principle: as locomotive means.

Suction cups are elements that base their operation on the difference of pressure existing between the internal volume and the environment. The so called vacuum action is actually due to the difference of atmospheric pressure that pushes the suction cup against the surface and the absolute pressure remaining inside the volume of the suction cup itself. The coupling between two bodies with a certain normal force gives then birth to a friction between the bodies themselves that is function of the force and of the friction coefficient between the two materials; friction forces have then tangential direction and contribute to define the real loading capacity of the suction cup.

Any use of suction cups will then provide for an accurate dimensioning to avoid exceeding the load capacity and resulting in a detachment. In modern handling systems we increasingly use suction cups as gripping system, they are widely diffused in packaging machines just in virtue of their elasticity and of their capability of suiting non optimal operation conditions. The driving sector for vacuum pneumatics is certainly the food industry, the suction cup technology succeeds in satisfying the more and more exacting demands and in suiting the unavoidable demand changes that are very frequent in this field.

The robot alternative

The scientific research in the robotic industry has considered suction cups for years as an effective gripping means for a use that is technically the opposite to the typical one of the industrial environment: the above mentioned packaging machines are a striking example. The suction cup is positioned at the end of the robotic system and is used to seize components. An anomalous use of suction cups is instead the anchorage of the robot itself: the working conditions are different owing to the different loads and the different arrangement of elements and it is introduced a further element of complication residing in the correct balancing of forces. A robot that uses suction cups as its own anchorage system is affected by these problems and needs a control able to distribute the load among the various suction cups in order to avoid that a wrong arrangement of anchorages generates a localized increase of the load leading to the detachment of one element. The research on the field has generated a notable increase of solutions, some of which will be later on examined here; the trend in the study of such robots consists in implementing systems able to move in non-structured environments and we can see a large use of unconventional suction cups able to grip several surfaces while permitting a generous air leakage.

Some case studies

The scientific research has produced different typologies of implementation solutions for mobile robots intended for the motion on surfaces, both flat, curved or with obstacles. We are presenting here some valuable solutions that are based on the theory of suction cups where we examine the various anchorage possibilities of the above mentioned systems, paying utmost attention to pneumatic systems.

The traditional concept of robot is anthropomorphic, all robots that are based on standard concepts are composed by a more or less structured range of elements that recall the arrangement of human limbs or of animal paws. The most appreciated figure is the spider, the majority of self-propelled robots essentially mirrors the structure of an arachnid with an even number of arms arranged according to an axial or central symmetry around a base platform. A good example is constituted by the Hydra robot [5], manufactured by HannoverUniversity, able to climb on vertical surfaces. Equipped with four suction cups, one for each paw, it can overcome obstacles with height up to 4 cm.

Another interesting system is represented by the Oktoput robot, developed for cleaning glass surfaces of cruise ships; it features two sliding surfaces in relative motion and can move towards any direction. 1-metre long, it weighs about 140 kg at full load and is powered by a single 220 V electrical cable, it moves at around 1 metre per minute and it is equipped with an effective cleaning system with rotating brushes; the anchorage system uses 8 suction cups. At Chile University, a group of researchers supervised by professor Armada [2] has implemented a robot used in the petrochemical industry constituted by more bodies in relative motion one another; designed for inspections of pipes and tanks of liquid gas, it can move along vertical walls and horizontally thanks to the use of various gripping technologies including suction cups.

Atypical robots

The research has also produced original results like the two sucking robots that follow. In the Nineties the laboratory of the professor Nishi [3] in Japan constructed a robot able to cling on the external walls of buildings and to move along the surface like a vehicle, using rotating wheels and motors. The robot draws the air from a chamber obtained underneath and acts similarly to a hovercraft, keeping in touch with the surface a deformable sealing able to separate the underside of the robot from the external environment. A generous suction obtained through fans makes the robot adhere to actually any surface. A similar system has been developed by the ScienceAcademy in Moscow and operates thanks to a fan that keeps in depression the volume enclosed under the robot carter shaped like a bell. [1]. The robot motion is obtained by means of two wheels controlled in speed that can impress a linear motion to the object or a rotation on the plan. The described module can transport service modules constructed for various functions including the cleaning of the glass surface.

The Winclimb project

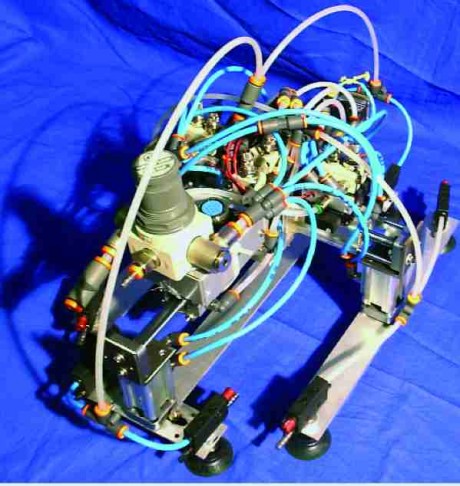

At the Politecnico di Torino they have implemented a robot able to move in semi-structured environment that uses suction cups as only supporting means. We are speaking of the Winclimb project that started in the far-off 2004 and resulted in a prototype able to move easily on smooth vertical surfaces like glass windows. Designed for a domestic use, Winclimb has proved to be a useful demonstrative platform for the concept of a system able to clean medium-large size glass surfaces. Winclimb was made according to the characteristics of the surfaces to be treated, that’s to say rectangular shapes whose sizes do not decrease under the linear meter of side. The degrees of freedom of the system are reduced to two. The weight requirements coupled with the need of limiting the invasive effect on the domestic environment led to the choice of the pneumatic technology both for the drive and for the anchorage to the glass surface. The Winclimb robot uses in fact four pairs of suction cups powered through a series of ejectors originally planned in number of 8 and afterwards reduced to four. The design of the anchorage system of this robot needed a notable work of research on the technical characteristics of the anchorage by means of suction cups. Different typologies of suction cups were considered, especially taking into account two essential requirements, which were the gripping capability in wet environment and the reduced visual impression of the suction cup on the material.

They selected suction cups that had been designed to take hold on greased sheet metal, fabricated with a special polyurethane compound that does not leave any impression on the surface like halos or similar. The original suction cups had a diameter of 35 mm, then increased to 55.

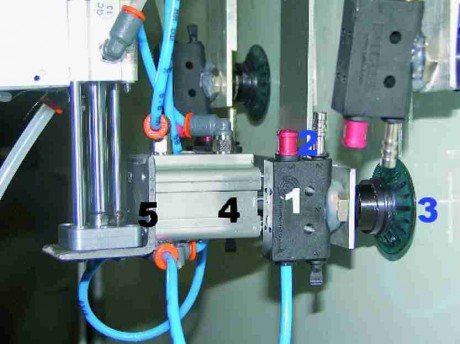

The vacuum pneumatics was not applied only in the section dedicated to the bearing but it is also used to dry the glass after cleaning. An innovative system, based on the Coanda effect, allows in fact removing, by means of an air blade, the water drops that remain on the washed surface and conveying them into an apposite collection carter to allow their recycling.

The system, constituted by a circular profile 1 along which the air slides, can impress a curved trajectory to the air itself after that the latter has pulled the water away from the glass surface . www.polito.it

References

[1] Gradetsky V., Rachkov M., Kalinichenko S., Semenov E.: “Service robot for cleaning vertical surfaces” IARP Workshop, Genova, October, 1997, pp. 120-126.

[2] Armada M., Gonzales de Santo P., Prieto M. : Climbing and walking robot for the petrolchemical industry and for underwater applications, CLAWAR Newsletter 2002 p. 939.

[3] Nishi A. : Development of Wall-climbing Robots, Computers Elect. Engineering Volume 22, pp. 123-149, 1996.

[4] Cepolina F., Michelini R.C., Molfino R.M., Razzoli R.P. (2000): “Collie-Gecko: a co-operative multi-robot systemfor cleaning applications”, Proc. 3rd CLAWAR 2000, Intl. Conf. on Climbing and Walking Robots, Madrid 2-4 Oct. 2000.

[5] Un robot “scalatore” Rivista di Meccanica N° 1074 Maggio 1995.