Specialized in power transmissions, Transfluid makes available its know-how and its products in over 50 Countries in the world. Also in Australia, where since last year it has been present with its own operational branch.

Reference partner in the sector of industrial transmissions and of its components, Transfluid can boast an experience lasting over half century. Founded in 1957 in Milan, since then it started in fact its production that, in time, has found widespread success all over the world. An organizational structure that today is composed by Gallarate headquarters (Varese, Italy) and by property subsidiaries located in the United States, China, France, Russia, and by a technical office in Brazil.

«An expansion– specifies Mr Ugo Pavesi, general manager of the Group – fruit of a targeted growth strategy, started at the end of the Nineties and developed with the precise goal of being able to offer not only commercial services but also after sale service and a spare part centre. This thanks to the presence of small but anyway well-stocked and flexible warehouses».

A strategy of constant expansion that sees the establishment of the Russian branch (occurred in 2007) followed by the setup of the subsidiary in Australia last year: a clear consolidation of the continuous and constant growth of the company. The new branch was inaugurated in the first semester of last year in the metropolitan area of Sidney, in New South Wales.

«Registered with the name Transfluid Australia Pty Ltd – explains Mr Pavesi – the new subsidiary provides sales and after-sale service and support, for all of our products on the Australian territory and in Philippines, too ».

The company is in fact provided with offices and warehouse permitting to shorten the delivery times for some products and to grant a prompt after sale service thanks to the stock of spare parts.

«A huge investment – further adds Mr Pavesi – that represents a relevant step forward in our growth. A project that provides, in the lapse of 5 years, for the capability of generating about 10% of the consolidated turnover of the Group in this continent».

With what product typologies?

«We believe that at these latitudes our whole range of hydrodynamic couplings in their various configurations, such as starters or speed variators, as well as alignment couplings and brakes, can arouse lively interest – specifies Mr Pavesi».

Made in Italy competence

More in general Transfluid can boast a wide range of products for the most different and demanding applications. Hydrodynamic couplings, speed variators, brakes, clutches, gearboxes, couplers and flexible couplings have been the strong points of the company over the years, also thanks to the support and the competence of a technical department where skilled engineers and designers are committed to solving, in short times, each type of applications. They have then conceived innovative solutions welcomed with positive acknowledgements and success in several ambits. Like in the case of the recent presentation of a complete range of hybrid transmissions to the market (see box), dedicated both to industrial and shipbuilding applications.

«They are three – specifies and ends Mr Pavesi – the main available sizes for these transmissions. A complete “package”, suitable for satisfying the needs of medium-low powers, of which we own the whole know-how and engineering. Our technical office has in fact designed and developed not only the whole part of software coding, but also electronics, with a hardware base that is the same used also on other products of ours».

Important strong point is in fact the almost total use of standard components, including the electrical machine that, skilfully assembled, results in an innovative, complete and performing system. The Italian cleverness and dynamicity of Transfluid, coupled with the competence and the constant updating of its technical staff, where a team of around fifteen people works, are the fundamentals on which the company has always based its success; about one hundred are instead its global employees who, engaged in the headquarters and the various branches, contribute to generate a global turnover that amounts to about 25million Euros. A figure that, according to the management of the company and the plans just launched, is expected to double in the next five years.

Hybrid, complete and performing

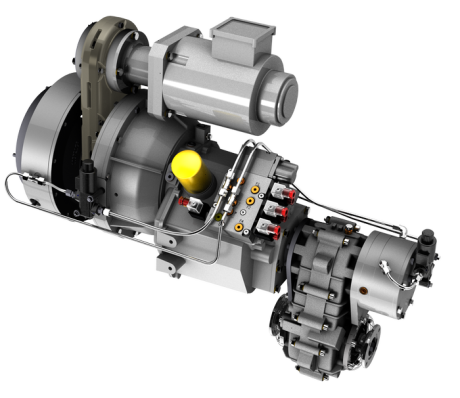

Fully designed and developed by Transfluid, HT-700 is the concrete example of the easy implementation of a complete hybrid transmission line. An execution that employs all the products of the Italian company and that can find application in those vehicles that must respect “green” zones for part of their journey. In this case, the power of the endothermic motor can perform 95 kW or 127 hp, while the electrical machine reaches 20 kW or 27 hp.

The HM-560 version represents instead the simplest item you may think; it is studied to be coupled with whatever endothermic motor (up to 140 kW or 188 hp), having a SAE flywheel and bell and any type of transmission gear, it too compliant with the SAE standard. Moreover, the position of the “electric machine” (up to 20 kW or 27 hp), so called in virtue of the fact that it can operate both as motor and as generator, can be rotated by 360°, in order to find the best position within the overall dimensions of the vehicle or of the boat. What you need are just 300 mm of space to introduce it. Therefore, both existing vehicles and boats and new designs: gearboxes, either mechanical or power shift, hydrostatic transmissions, marine inverters, all can be easily coupled with HM-560.