Aignep joins for the first time Hannover EMO for the promotion of its pneumatic and mechatronic solutions

This year, and for the first time, Aignep joins Hannover EMO the worldwide biennial exhibition for tooling machine. This is a strategic decision that looks at the growth, both commercial and technical. The aim is to face the market as a potential unique source for any partner, thanks to the complete range that goes from pneumatics to automation. The main industrial focus for Aignep are: Packaging, Automotive, Food & Beverages and, according to the EMO participation, Tooling Machine OEM.

The evolution of Aignep in the recent years includes on one hand the commercial approach, adding to his distribution network a structure of direct service to the end customers and OEM. Accordingly, in recent years Aignep strengthen its commercial structure and opened several branches (USA, Spain, Switzerland, Brazil, France and Colombia). Proximity to the client, together with the ability to quickly solve any Kind of problem, are known a “must” for Aignep. Thanks to this Aignep is able to develop also new projects and customized solutions.

On the other hand Aignep is always focused in enlarging its range. Historically recognized as one of the leader in the production of fittings, Aignep covers the field of the mechatronics, thanks to the introduction in its range of products that are more and more technologic. Among them: fluid control valves and island valves with the most popular connection protocols. In this context the last news is the 15V series (that will be exposed also in EMO): compact and modular, this is a products that offers high performances, quick communication time and easy setting with the control tools of the machines, both PLC and CNC. The 15V is available in 4 different communication standard: 37pol connection, Profibus and will be soon available as Profinet and EtherNet/IP.

New 730 series, energy saving oriented, allows to improve the flow rate till, up to 25

Aignep is launching the new 730 series, quick couplings oriented to the energy saving thinking: thanks to the special construction off the shutter, 730 series allow the improvement of 25% of the flow rate if compared to the standard one with the same profile .The shutter have been designed with the same components and dimension, but their position have been improved, this allows to avoid obstacles that can obstruct the flow. Accordingly, is possible to obtain more flow power using less compressed air energy. The new 730 series have been launched in Hannover Messe 2017 and they will be effectively on the market in the next few months. At the moment this technology is applied only on the German profile, but it will be enlarged to all the most important profiles (Italian, Swiss, B12 ISO suitable for the North American market) and improved for all automatic quick couplings of Aignep.

Ad hoc project

The project of the special shutter is the result of a near one year of studies and analysis conducted by Aignep’s R&D department. The outcome is the absence of any kind of obstacles and interferences to the flow of fluid improving the flow rate, Aignep did this by applying a better disposition of the components inside the shutter.

From a esthetical point of view, thanks to a special molding, the shape of the shutter is narrow and clean. In fact, order to improve the flow rate it has been necessary to adopt a different material from the standard one. Therefore there has been a material change from turning machine worked brass to diecast zamak (molded and nickel-plated), with the aim to obtain more flow resistance and avoid condensate.

A different disposition of the inner springs has been important to avoid obstacles to the flow: they are now mounted along the inner perimeter of the body, instead of in the center. The achievements can be shown in the fact that this new 730 series allows the same profile to ameliorate the standard flow rate, reaching 2.550 Nl/min that are far more efficient from the market standard 1.900Nl/min.

Another advantage is that this 730 series can be applied also in vacuum application: contrariwise of the classic model, the special shutters allow this quick coupling allows a bidirectional management of the flow rate.

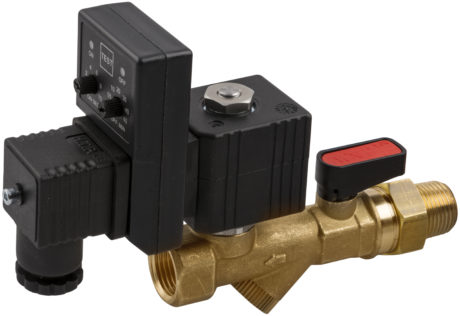

Infinity’s automatic drain valve: solution in one item

Today, when installers need to drain condensate settled in their machine and pipeline, they are forced to apply a kit of components: a ball valve, a solenoid valve and a timer. Moreover, they have to connect every components with adaptors. The outcome of this practice is a complex procedure that makes installation and maintenance difficult (specifically for mounting/dismounting and filter change).

In order to overcome this problem, Aignep has successfully designed an automatic drain valve that is single-body composed: this is the 90975 series, specifically thought to complete the Infinity line. It has been launched during Hannover Messe 2107. With this automatic drain valve all the installation and maintenance operation are simpler, quicker and with less damage risks.

Quicker mounting, maintenance and dismounting

The body of the 90975 series valve is entirely realized in brass, this allows the new product to be a suitable solution for all the most popular applications of the industry. A fine and precise working gives the valve a unique and clean design. The pilot, the magnet core and spring are instead made by stainless steel. Seals are in NBR. Thanks to this automatic drain valve, in just one item is possible to find: solenoid valve, timer and ball valve (equipped with the filter).

The easiness of mounting/dismounting and maintenance is one of the main characterizing factors of the 90975 series. In fact it is possible to fix the automatic drain valve to the application with an hex key and to connect the end with a fitting, thanks to the swivel body it’s extremely easy to orient the product in the right position. This allows a quicker maintenance and cleaning of the product and it helps any kind of dismounting necessities. Moreover the special design of the body allows smooth operations with the hex key.

90975 series are designed to be applied to the most popular industrial application: compressors, drier, filtration unit and air pipeline; in any place where condensate drain is a must.